脉冲宽度调制(PWM)调光是一种用于控制 LED 亮度的流行技术。由于其效率高、能够提供精确的调光控制,因此被广泛使用。本文将探讨 PWM 调光、其优势、技术细节以及与其他调光方法的比较。

用于 LED 驱动器的 PWM 调光使用的是脉冲宽度调制。它通过高频率开关 LED 来调节 LED 的亮度。通过改变占空比,LED 的平均功率发生变化,从而控制亮度。PWM 调光因其效率高而备受青睐。它能精确控制 LED 的亮度。这使它适用于许多照明应用。

为了更好地理解 PWM 调光,我们需要深入了解其工作原理的具体细节,以及为什么它比其他方法更受青睐。

关于调光的见解

恒定电流降低 (CCR)

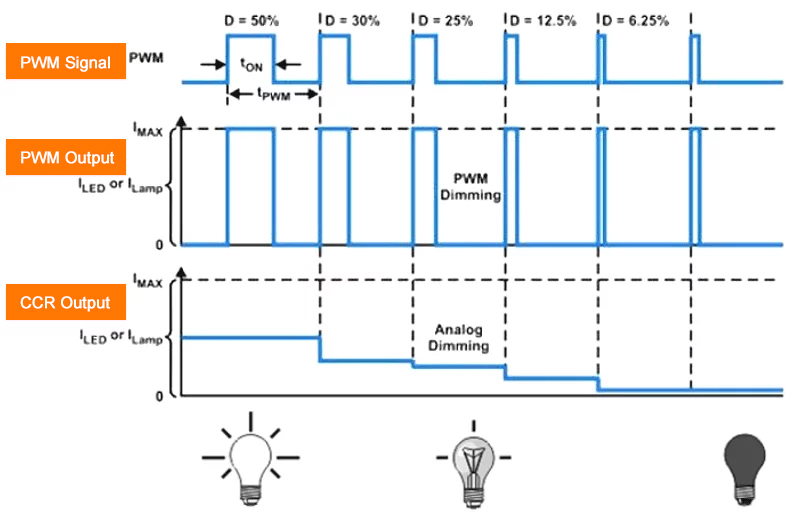

LED 的调光方式多种多样。最常见的是恒定电流降低(CCR)和脉冲宽度调制(PWM)。CCR 可减少提供给 LED 的电流,从而降低其亮度。这种方法很简单。但它可能会改变 LED 的颜色和效率。降低电流可能会导致 CCR 改变 LED 的颜色或降低其亮度。此外,这种方法可能会产生更多热量。这些热量可能会缩短 LED 元件的寿命。

恒流减速器可应用于以下领域。

- 驾驶员远离电源的情况

- 潮湿区域和户外应用

- 电磁干扰(EMI)标准严格的地区

脉冲宽度调制 (PWM)

另一方面,PWM 调光通过快速开关 LED 来控制亮度。通过改变 PWM 信号的占空比来调整 LED 的平均功率。这种方法能保持颜色的一致性,而且效率更高,因此在许多应用中成为首选。PWM 调节脉冲宽度。它能确保 LED 在短时间内获得稳定的功率。这样,LED 就能保持其色彩。此外,PWM 可以很容易地由数字系统控制。这使其与现代电子控制和智能照明系统高度兼容。

PWM 应用于以下领域

- LED 驱动器调光

- 太阳能电池板

- 发动机

什么是 PWM 调光?

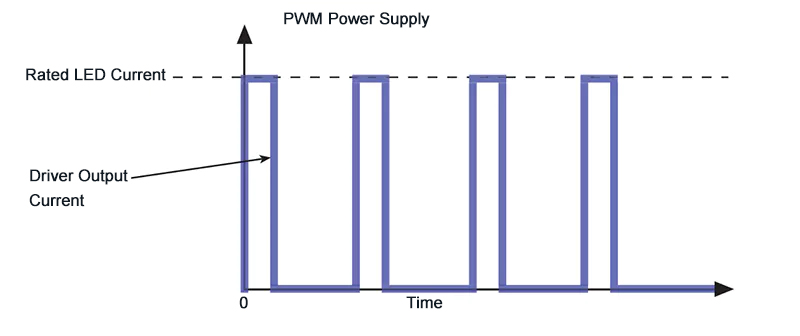

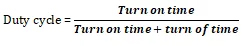

PWM 调光是利用方波信号来控制 LED 的功率。信号以高频率在开启和关闭状态之间切换。占空比是信号开启的时间比例。它决定了平均功率,从而决定了 LED 的亮度。例如,如果占空比设置为 50%,LED 将有一半时间处于开启状态,另一半时间处于关闭状态,从而产生 50% 的亮度。它的开关速度很快。人眼看到的是调光效果,而不是闪烁的光。

例如,50% 占空比意味着 LED 亮一半,灭一半,亮度为 50%。通过调整占空比,可以实现对亮度的精确控制。此外,PWM 调光并不局限于简单的开关模式。占空比可以平滑变化。这样就可以实现亮度的渐变。这对于需要平滑调光的应用非常有用。这些应用包括建筑照明或舞台照明。此外,微控制器还能实现 PWM 调光。这使它成为各种 LED 驱动器设计的通用器件。

为什么使用 PWM 对 LED 进行调光

PWM 可用于 LED 的调光,因为它有几个优点:

– 效率:PWM 调光不会以热量形式耗散功率,因此更加节能。模拟调光方法会将多余的功率转化为热量,从而浪费能源。PWM 能更精确地控制功率。它能确保将能源损耗降至最低。这种速度对于使用电池或便携式灯具至关重要。省电在这方面至关重要。

– 精确度:它能精确控制亮度级别。微调占空比的功能可实现从极暗到全亮的多种亮度设置。这种精度使 PWM 调光适用于需要精确控制照明的应用,如医疗设备、摄影照明和显示器背光。

– 一致性:保持 LED 灯的色温和质量。由于 LED 在 "开启 "期间始终以其全部额定电流工作,因此色温保持稳定。与模拟调光相比,这是一个显著的优势,因为模拟调光在较低的电流水平下会导致色差。在零售照明和博物馆展示等应用中,稳定的色彩质量至关重要。在这些应用中,准确的色彩至关重要。

– 兼容性:易于与数字控制器和微控制器集成。许多数字设备都能发出 PWM 信号。这些设备包括微控制器、PLC 甚至一些简单的定时器。这种兼容性使其可以轻松集成到智能照明系统和自动控制设置中,实现远程调光控制、可编程照明时间表和动态照明效果等功能。

这些优点使 PWM 成为理想的应用。应用范围从家用照明到工业和汽车。例如,在汽车中,PWM 调光用于仪表盘和前大灯调光。它还用于车内环境照明。它能在不断变化的条件下提供可靠、高效的控制。

LED 驱动器中 PWM 调光工作原理的技术细节

LED 驱动器中的 PWM 调光包括产生一个高频方波信号。该信号被送入 LED 驱动器,LED 驱动器根据 PWM 信号的占空比调节提供给 LED 的功率。LED 驱动器充当中介,确保 LED 接收到正确的功率,以达到所需的亮度。调制过程包括高速开关 LED 电流。接通 "时间的长短由 PWM 信号的占空比设定。

LED 驱动器通常包括一个微控制器或专用 PWM 控制器集成电路,用于产生 PWM 信号。PWM 信号的频率要选择得足够高,以避免可见闪烁,通常在 200 Hz 以上。在此频率下,开关转换太快,人眼无法察觉,从而产生平滑的调光效果。微控制器或 PWM 控制芯片可调整占空比。它根据用户输入或编程设置进行调整。这样就能实现动态、灵敏的 LED 亮度控制。

为确保性能可靠,LED 驱动器的设计必须能够处理 LED 负载的具体特性。这包括 LED 的正向电压。还包括额定电流和热需求。驱动器可能具有反馈功能。它可以监控 LED 的性能并调整 PWM 信号。这样就能在不同条件下保持亮度和颜色的一致性。此外,LED 驱动器还可能具有保护功能。这些功能包括过流保护、热关断和短路保护。它们可同时保护 LED 和驱动器电路。

PWM 作为调光信号:占空比和频率

PWM 信号的占空比是导通时间与信号总周期之比。例如,占空比为 25%,表示信号在 25% 的时间内导通,在 75% 的时间内断开。调整占空比可改变 LED 的平均功率,从而控制其亮度。占空比的灵活性使得亮度范围很广。从几乎关闭到完全开启。它可提供精确、平滑的调光控制。

PWM 信号的频率也至关重要。频率越高,调光越平滑,并能避免闪烁。在视频录制等有运动的应用中尤其如此。建议使用 25 kHz 以上的频率来实现无闪烁调光。在这些高频率下,PWM 信号的开关速度非常快。这种闪烁速度之快,人类和高速摄像机都无法察觉。这在专业照明设置中至关重要。闪烁会损害视频质量和观众的舒适度。

在实践中,PWM 频率的选择取决于 LED 的需求和使用情况。例如,在建筑照明中,1 kHz 左右的频率可能足以避免可见的闪烁。但在高性能视频照明中,可能需要 25 kHz 或更高的频率才能实现完美的性能。必须仔细校准占空比和频率。它们要在亮度、效率和无闪烁操作之间取得平衡。因素包括 LED 的响应时间和系统的热特性。

PWM 作为 LED 驱动器输出

在基于 PWM 的 LED 驱动器中,输出是与 PWM 信号相对应的调制电流。LED 驱动器将 PWM 信号转换成相应的电流,然后驱动 LED。这种方法可确保 LED 获得适量的电流。从而保持亮度和效率。调节电流可以精确控制 LED 的光输出。这可确保在各种亮度水平下都能保持稳定的性能。

LED 驱动器通过与 PWM 信号同步快速开关 LED 电流来实现这一目标。在 "开 "期间,LED 获得全电流,产生最大光输出。在 "关 "期间,LED 没有电流,因而没有光输出。驱动器可调整 "开 "和 "关 "的比例(占空比)。该控制可设定平均电流,从而设定 LED 的平均光输出。

这种方法有几个优点。首先,它能让 LED 在 "开启 "期间以最高效率工作,最大限度地减少能量损失和发热。其次,它能保持 LED 颜色的一致性,因为 LED 在 "开启 "期间始终以额定电流工作。第三,它能精确控制 LED 的亮度。这样就能实现平滑调光和动态照明效果。此外,基于 PWM 的驱动器可以轻松连接到数字控制系统。这样就可以对照明设置进行可编程和远程控制。

PWM 调光与其他调光方法的比较

与其他方法相比,PWM 调光有几个优点:

– 模拟调光:涉及调整提供给 LED 的电流。这种方法虽然简单,但可能导致色差,而且效率较低。模拟调光会逐渐减小电流。这会导致 LED 发出不同强度的光,并可能改变其颜色。此外,这种方法往往会消耗更多的热能,从而降低系统的整体效率。

– 相切调光:在交流供电的 LED 驱动器中使用,它可切断交流波形以降低功耗。它可能会引起闪烁和与某些 LED 驱动器的兼容性问题。相切调光的工作原理是切断部分交流波形,从而有效降低输送到 LED 的平均功率。这种方法会导致与某些 LED 驱动器的兼容性问题。这会导致闪烁和性能不佳。它还需要更复杂的电路来实现,这可能会增加照明系统的成本和复杂性。

PWM 调光效率更高。它还能提供精确控制并保持色彩一致。在许多应用中都有更好的效果。PWM 调光用高频信号调制功率。它避免了模拟调光和相切调光的问题。PWM 调光是一种更可靠、更灵活的解决方案。此外,PWM 调光还可与数字控制系统配合使用。它可以实现可编程调光配置文件、远程控制以及与智能家居系统集成等高级功能。

在市场中实现 PWM 调光驱动器

PWM 调光驱动器在 LED 照明中越来越重要。不过,我们必须明白,有两种不同的方法可以实现 PWM 调光驱动器。让我们来探讨一下这两种方法。

假 PWM 调光

假 PWM 调光方法是将 PWM 输入转换为模拟控制信号。这种方法在驱动器内使用电阻电容 (RC) 滤波器。RC 滤波器可将 PWM 信号平滑转换为与占空比成比例的直流电压。假 PWM 调光的一个优点是无噪声,因为 LED 电流在输出端保持连续。

然而,这种方法有很大的缺点。PWM 信号的峰值必须为 10V 以确保精度,这可能是一个限制。此外,RC 参数还限制了 PWM 信号的频率。这就降低了调光系统的灵活性和性能。

真正的 PWM 调光

在真正的 PWM 调光中,LED 电流以指定的频率和占空比开关。驱动器内的微控制器 (MCU) 可检测 PWM 信号的峰值电压,从而实现精确控制。真正的 PWM 调光支持更宽的 PWM 频率范围,并能保留 LED 输出的白点。它还能容纳更高的基准电压,减少偏移误差。

例如,所有 boqi 驱动器都集成了一个 MCU,以实现真正的 PWM 调光。这使其驱动器能够接受从 3.8V 到 10V 的各种 PWM 信号电压,从而兼容各种 PWM 信号,如常用的 5V PWM 信号。

用户需要在驱动器编程软件中选择 PWM 调光模式,才能使用该功能。

结论

总之,PWM 调光是一种有效且高效的 LED 亮度控制方法。它的精确性和适应性使其成为各种应用的首选。了解其原理和优点有助于选择适合您需求的调光解决方案。选择像 boqi 这样信誉良好的供应商。他们能确保您获得高质量的 可调光 LED 驱动器.这些驱动器性能卓越,可靠性高。