Welcome to our comprehensive guide to LED dimming. If you’ve ever marveled at the soft glow of dimmed LED lights and wondered how it’s done, you’re in the right place!

Introduction to LED Dimming

LED dimming is all about manipulating the output of a lighting fixture. It’s not only about creating the perfect ambiance; dimming also plays a significant role in saving energy and reducing costs. Fascinating, right? Let’s delve deeper!

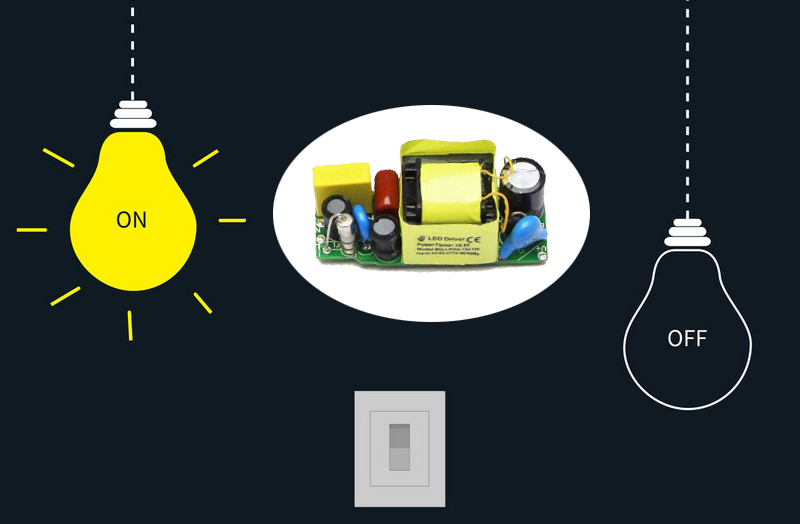

The Dual Function of LED Drivers

You might be wondering, what do LED drivers have to do with all of this? Well, they play a dual role. First, they act as power converters, transforming input from the mains into low outputs suitable for LED lights.

LED Driver as a Power Converter

As power converters, LED drivers ensure that LEDs receive the right amount of energy. Too little, and they won’t shine brightly; too much, and they could burn out.

LED Driver as a Dimmer

Secondly, LED drivers act as dimmere, controlling the amount of energy entering the LEDs. This ability to regulate energy makes LED drivers instrumental in saving energy and reducing power costs. They’re like the conductors of an orchestra, directing the flow of energy to create a perfectly lit room!

Two Main Methods of Dimming: CCR and PWM

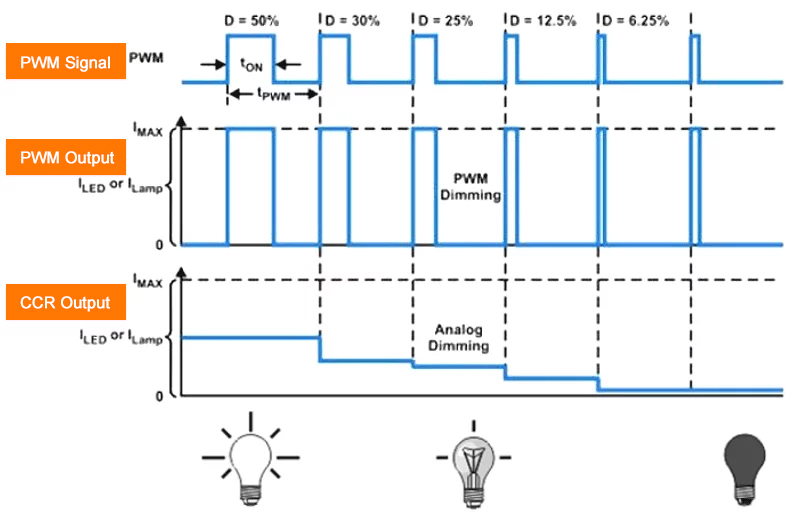

Dimming an LED light is no child’s play. There are primarily two ways to dim an LED driver, Constant Current Reduction (CCR) and Pulse Width Modulation (PWM). Both methods have their strengths and applications, and the choice between them often depends on specific circumstances.

In-depth Look at Constant Current Reduction (CCR)

Let’s take a detour and take a closer look at the first method, CCR. It’s also known as analog dimming. The key idea behind CCR is pretty simple: if you reduce the current flowing through the LED, you reduce its output, and voila, you have dimming!

Pros and Cons of CCR

CCR is often preferred in situations where the drivers are far from the power source, in damp areas, and outdoor applications. It’s also the go-to choice in places with strict electromagnetic interference (EMI) standards. However, the downside to this method is that color fidelity can be affected when dimming high-brightness white or single-color LEDs.

Understanding Pulse Width Modulation (PWM) in Detail

Next on the menu is PWM. Unlike CCR, which reduces the current, PWM dims by rapidly switching the current between on and off. The main power supply to the LED doesn’t change; instead, the duty cycle of the current does. That’s the pulse width modulation technique in a nutshell.

Pros and Cons of PWM

PWM has a wide range of applications, from LED driver dimming and solar panels to motors. The significant advantage of PWM is that it maintains color fidelity throughout the entire dimming range. However, the downside is that it may produce more EMI than analog dimming, so it requires careful design and testing for EMI compliance.

Deep Dive into PWM Dimming

Having understood the basics, let’s go a step further into the intricacies of PWM dimming. PWM dimming is all about adjusting the current in LED drivers using the PWM mechanism. Consequently, the LED driver becomes dimmable, providing flexibility and adaptability in lighting design.

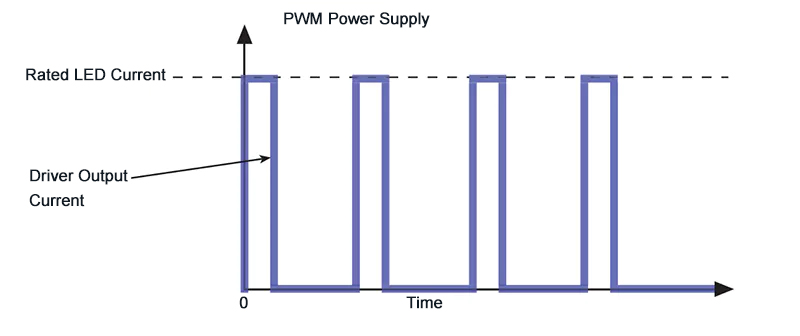

PWM switches the current at a high frequency, ranging between 0 and the maximum output, or the rated current. This creates a ratio of on-time to off-time, which controls the LED brightness.

Pulse Width Modulation as a Dimming Signal

Think of pulse width modulation signals as trains of pulses, forming a beautiful series of square waves. Each signal consists of a high point and a low point. The duration the signal stays high is the ‘on-time,’ while the length it stays low is the ‘off-time.’

Importance of Duty Cycle in PWM

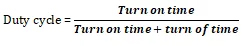

How Duty Cycle Impacts LED Brightness

In the PWM world, the measure of time the signal remains high is called the duty cycle. For instance, if a signal is constantly on, that’s a 100% duty cycle. You can control the on-time of a PWM signal. Say, if the PWM duty cycle is set to 50%, it means the signal operates 50% on-time and 50% off-time. It’s essential to note that the duty cycle can vary from 0% to 100%.

Here is an image for a better

The Role of Frequency in PWM Signal

How Frequency and Duty Cycle Interact

Another significant aspect of the PWM signal is its frequency. The frequency dictates how fast the PWM signal completes a cycle, where a cycle is the total time taken for the signal to go on and off. Balancing the duty cycle and frequency of the PWM signal enables a dimmable LED driver.

PWM as LED Driver Output

From PWM Signal to LED Brightness Control

When the PWM signal is converted into a DC voltage, it results in a PWM LED driver output. This circuit chops the DC LED currents at high frequency between the on and off state. Interestingly, the human eye cannot notice this high-frequency flickering, resulting in a change of the LED light output.

Conclusion: The Significance of Understanding PWM Dimming in LED Drivers

In the ever-evolving world of lighting technology, understanding PWM dimming is vital. Not only does it help in energy conservation, but it also significantly enhances the flexibility of lighting design. By leveraging PWM dimming, one can create varied lighting atmospheres while ensuring energy efficiency.

Now that you’re equipped with this knowledge, you’re all set to embark on your journey in the LED lighting world. Always remember, every light dimmed not only contributes to energy saving but also paves the way for a sustainable future.

FAQs

What is the difference between CCR and PWM dimming?

CCR dimming works by reducing the current, while PWM dimming works by rapidly switching the current on and off.

Which dimming method maintains color fidelity?

PWM maintains color fidelity throughout the entire dimming range, which can be a significant advantage in some applications.

What is a duty cycle in PWM?

In PWM, the duty cycle is the measure of time the signal remains high or ‘on.’

How does frequency impact PWM dimming?

The frequency determines how fast the PWM signal completes a cycle. Balancing the duty cycle and frequency of the PWM signal enables a dimmable LED driver.

Can the human eye detect the flickering in PWM dimming?

No, the human eye cannot notice the high-frequency flickering in PWM dimming, resulting in a smooth change of the LED light output.