LED Driver & Dimmer Manufacturing

Enjoy the Journey of An LED Dimmer From Parts to Product

Learn how boqi manage the whole manufacturing process of LED drivers and LED dimmers, and complete your order on budget and on time, batch after batch.

Design & Engineering

Sampling & Verification

Controlled Assembly

Comprehensive Testing

LED Driver Manufacturing

At boqi, every LED driver is built through a precise and standardized manufacturing process. From component sourcing to final assembly, each step is strictly monitored to ensure stability, safety, and performance.

Our production lines operate under ISO-certified management, integrating advanced automation with skilled craftsmanship. Every unit undergoes comprehensive testing — including power, dimming, and reliability verification — before delivery. This commitment to precision manufacturing guarantees LED drivers that perform consistently and stand the test of time.

LED Dimmer Manufacturing

Every LED dimmer at boqi is crafted with precision and reliability in mind. From circuit design to final assembly, each process follows strict international standards to ensure seamless performance and durability. Our engineers integrate advanced dimming technologies — including TRIAC, 0-10V, and DALI — to achieve smooth, flicker-free control across different lighting systems. Each unit undergoes comprehensive testing for dimming range, linearity, and compatibility to guarantee consistent user experience. With Boqi’s rigorous manufacturing and inspection system, every dimmer delivers professional-grade stability and comfort lighting performance.

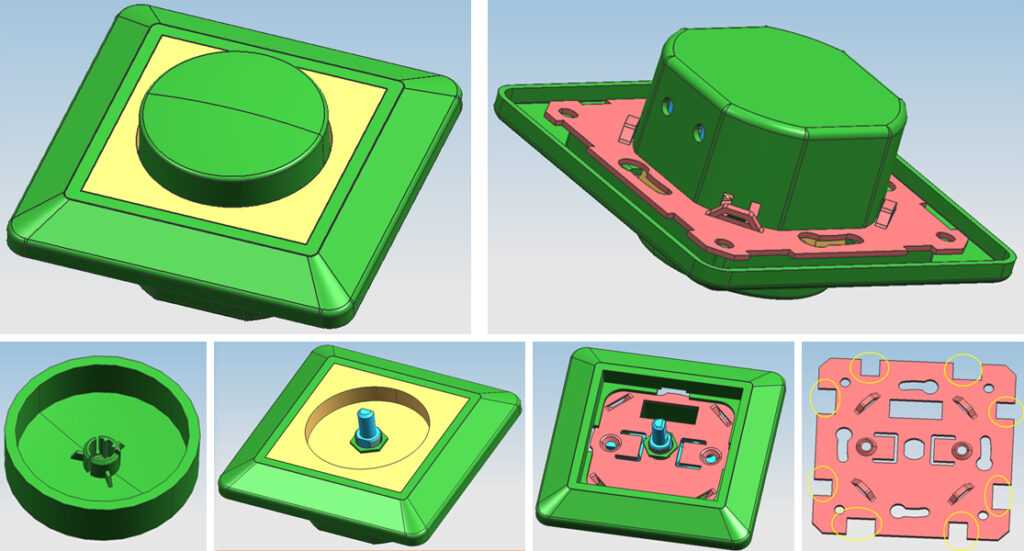

LED Dimmer Housing Manufacturing

Realize a unique shape to your light

Mold Design & Development

Each housing begins with a custom mold design created by our in-house engineers. The design focuses on perfect fit, heat dissipation, and ergonomic user interaction. Every mold is verified for dimensional accuracy and durability before entering production.

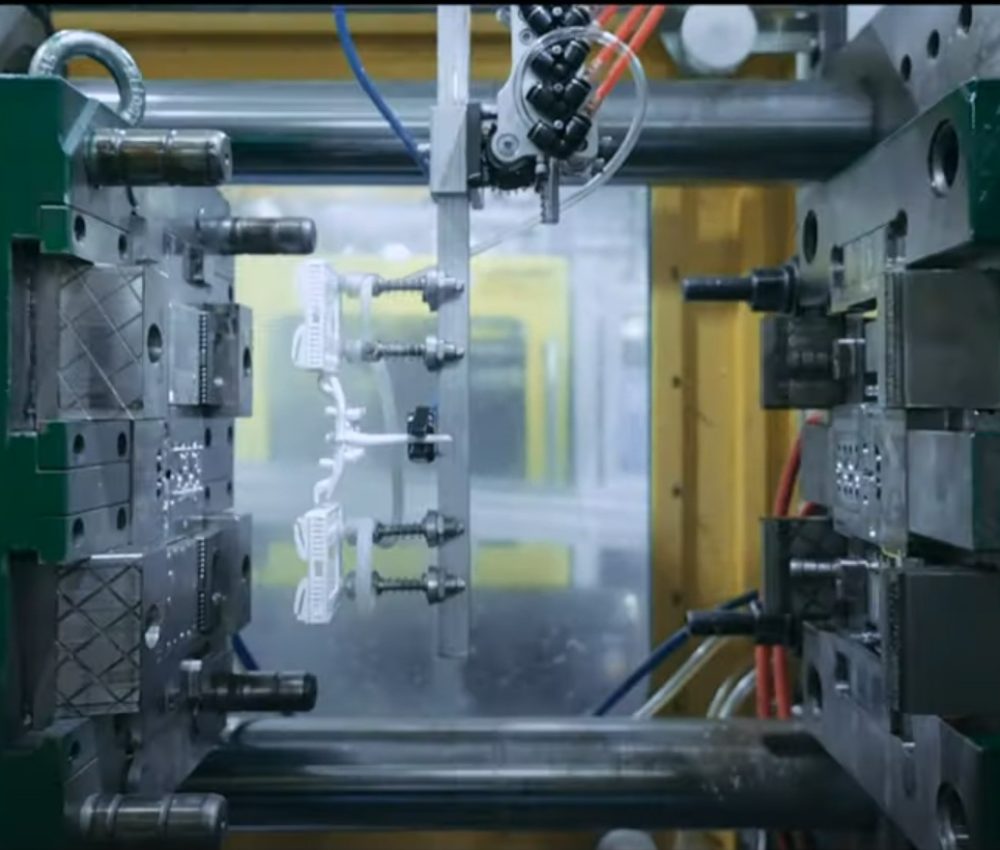

Material Selection & Injection Molding

We use high-quality flame-retardant PC materials that provide excellent insulation, impact resistance, and long-term stability. Advanced injection molding machines ensure consistent shapes, smooth surfaces, and minimal deformation.

Surface Treatment & Finishing

After molding, housings go through fine surface treatments such as polishing, matte finishing, or UV coating to enhance appearance and scratch resistance. The result is a clean, modern finish suitable for residential and commercial interiors.

Inspection & Assembly Preparation

Each housing is carefully inspected for dimensional precision, color uniformity, and mechanical strength. Only qualified housings move to the assembly line, ensuring every LED dimmer achieves Boqi’s high standard of quality, safety, and visual refinement.

Testing and Packaging

Every boqi product undergoes full functional and safety testing before delivery. Only qualified units are carefully packaged with bubble protection, ensuring safe transport and flawless performance upon arrival.

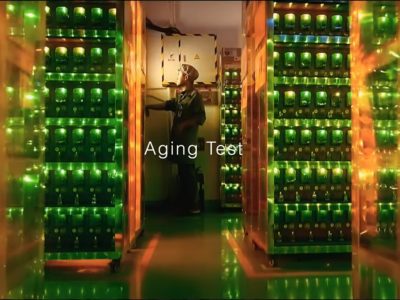

Aging Testing

Packing

Finished Products

Want To Be the Next Winning Brand?

boqi’s LED drivers, LED dimmers and services give you an absolute edge over your competitors.