Navegar por los entresijos de Controlador LED La selección es un tema de gran importancia en el ámbito de la electrónica y la iluminación. A primera vista, el proceso puede parecer sencillo. Sin embargo, encontrar un controlador adecuado que se adapte a la perfección a un producto de iluminación optimizado exige una atención meticulosa.

In reality, the procedure encompasses multiple stages. It's imperative to meticulously examine each step delineated, especially if the objective is to identify a driver that resonates with the voltage waveform and phase control requirements of a sophisticated LED lamp system.

- 1. Determinación de la solicitud

- 2. Modo de corriente constante o tensión constante

- 3. Selección de la potencia nominal:

- 4. Especificación de la tensión de salida

- 5. Especificación de la corriente de salida

- 6. Decisión sobre el tipo de cable

- 7. Selección de la certificación

- 8. Elección del método de regulación

- 9. Verificación de muestras

- 10. Evaluación de la calidad y el servicio

1. Determinación de la solicitud

Firstly, it's imperative to discern whether you're in the market for an outdoor or indoor driver. While the term "outdoor driver" might suggest exclusivity to external environments, it typically pertains to an IP66 or higher waterproof rating, coupled with a 2kV differential mode and 4kV common mode surge protection rating. Outdoor drivers predominantly find their place in bay lights and explosion-proof lighting. Conversely, indoor drivers, when equipped with robust surge protection, can be adapted for outdoor usage. Nevertheless, the terms "outdoor" and "indoor" remain the prevalent descriptors for lighting applications.

2. Modo de corriente constante o tensión constante

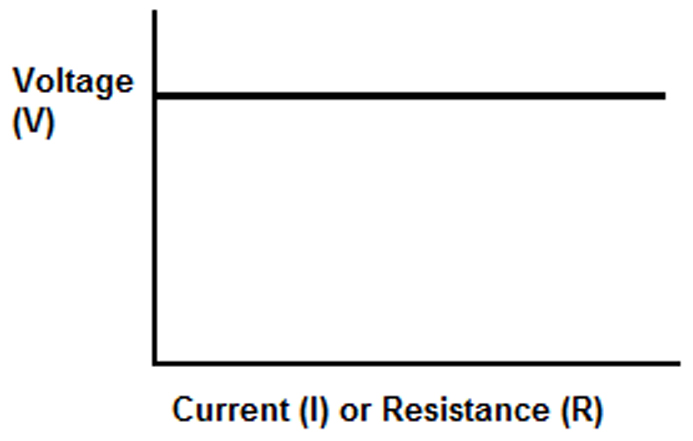

In the realm of electronics and lighting, choosing between Constant Current (CC) and Constant Voltage (CV) modes for LED drivers is crucial. The CC mode ensures a consistent current, vital for LEDs to maintain uniform brightness and longevity. Conversely, the CV mode, ideal for setups with multiple LEDs or strips in parallel, provides a set voltage output. Each LED or strip in such designs draws its required current from this voltage source, but it's essential that each has its own current-limiting mechanism. The decision between CC and CV depends on the lighting system's demands: CC focuses on precision for individual LEDs, while CV emphasizes flexibility for larger setups. Understanding these modes is key for optimal LED system performance.

3. Selección de la potencia nominal:

For LED lamps, the power rating invariably alludes to the input power. However, when discussing LED drivers, one refers to the output power, which is the product of the output current and the maximum output voltage. The key is to ensure that the chosen power surpasses the LED's peak load power.

4. Especificación de la tensión de salida

Choosing the right output voltage specification for an LED driver is crucial for the optimal performance and longevity of LED lighting systems. The LED driver serves as the power supply for the LED, converting input power to the correct voltage, current, and frequency required by the LED. When selecting an LED driver, one must ensure that its output voltage matches the voltage requirements of the LED or LED array it will power. Mismatched voltages can lead to reduced brightness, color shifts, flickering, or even premature failure of the LED. Moreover, it's essential to consider the operating environment, as voltage requirements can change based on temperature fluctuations. Some advanced LED drivers come with adjustable output voltage settings, providing flexibility for various applications. In conclusion, by carefully selecting the right output voltage specification for an LED driver, one can ensure efficient energy use, consistent light quality, and extended lifespan of the LED system.

5. Especificación de la corriente de salida

This step is pivotal, largely governed by the type of LED chip chosen and its optimal operational point. Often, the desired current might not be readily available in driver model listings. In such instances, you're presented with two avenues: either select the closest available model or liaise with the driver manufacturer for a specific model. The former offers immediacy but might compromise on light performance, while the latter, though potentially time-consuming, ensures an optimal end product. The choice invariably hinges on the manufacturer's market strategy and specific circumstances.

If you aren't still sure about the specification of the LED Driver you need, please try to use our Calculadora de controladores LED!

6. Decisión sobre el tipo de cable

For the North American market, UL cables, predominantly with PVC jackets, are the norm. In contrast, other global regions tend to favor VDE cables with rubber jackets. It's worth noting that UL cables are globally accepted but face restrictions as standalone drivers under CE standards. The IEC standards introduce the class II device, devoid of a ground connection. When integrating connectors, it's crucial to be cognizant of their certifications. UL-certified connectors can be pricey, prompting some to opt for junction boxes for connections, especially in North America.

7. Selección de la certificación

Las certificaciones son primordiales. Para el mercado de la UE, CE es un requisito previo, mientras que UL es fundamental en otros lugares. ENEC suele considerarse superior en muchas regiones. La certificación CB tiene importancia por su fácil conversión a KC, PSE o SAA por un precio simbólico. En Norteamérica, una clasificación de clase 2 puede simplificar el diseño de las luces, similar a SELV en otros territorios del mundo.

8. Elección del método de regulación

This phase can be intricate for lighting engineers, given their expertise often leans more towards lighting mechanics than electronics and control. It's essential to ascertain the need for a dimming function and its realization, be it through TRIAC / Corte de fase, 0-10V, DALIo PWM. La elección de protocolo de control, cada uno con sus ventajas y limitaciones, depende de si el proyecto es novedoso o una adaptación. En un artículo posterior profundizaremos en estos protocolos.

9. Verificación de muestras

Upon concluding the electrical design, the journey isn't over. Acquiring and validating samples in your lighting system is the next step. It's advisable to order samples in batches, initially 2-3 units, to gauge product consistency. Post successful electrical performance tests, a larger batch can be ordered for a pilot run. The recommended size for a single run exceeds 50 units. Additionally, understanding product delivery timelines, especially for bulk orders, is crucial for both parties to ensure seamless production.

10. Evaluación de la calidad y el servicio

Before finalizing your decision, it's imperative to scrutinize the warranty, gauge the quality of customer service, and evaluate the vendor's ability to comprehend client needs. These factors play a pivotal role during and post the transaction.

boqi LED Driver se adhiere meticulosamente a los pasos antes mencionados, esforzándose por colaborar con usted en cada coyuntura. Nuestro objetivo es comprender sus necesidades en profundidad y presentarle la solución más adecuada. Esperamos fomentar una relación duradera. Si desea más productos de primera calidad, consulte nuestra oferta.

También hay disponible un tutorial en vídeo para quienes prefieran una experiencia de aprendizaje visual.