Design & Develop

Engine of Your Brand’s Sales

Design-Obsessed Team and Attitude

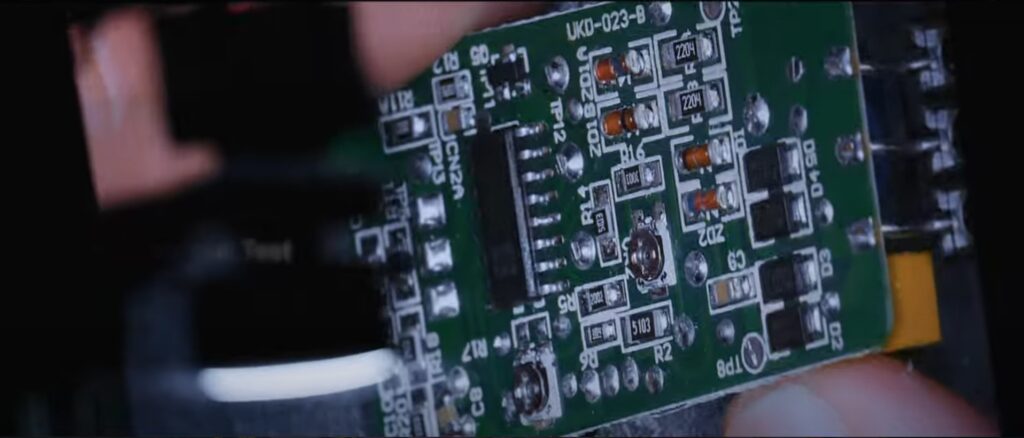

Innovation starts with understanding your needs at boqi. Our engineering team specializes in designing and developing customized LED drivers and dimmers that combine performance, safety, and aesthetics.

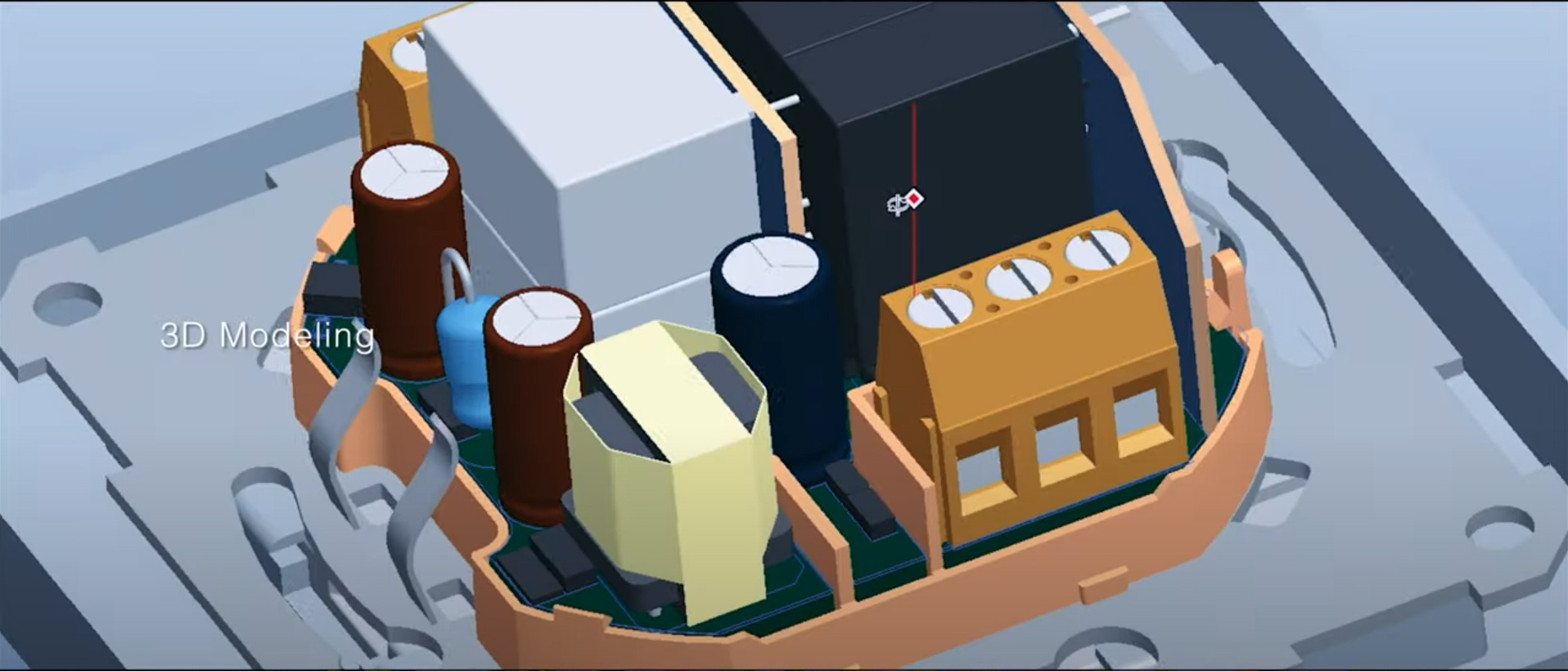

From circuit architecture to housing design, every detail is optimized for compatibility, efficiency, and reliability. Using advanced simulation tools and strict testing standards, we turn ideas into practical, market-ready lighting solutions that empower your brand to stand out in a competitive industry.

Every great product starts from listening to our customers and turning their ideas into reality.

-Zoe Zhu, CEO of boqi

Our Facility and Equipment Ensure Both Form and Function

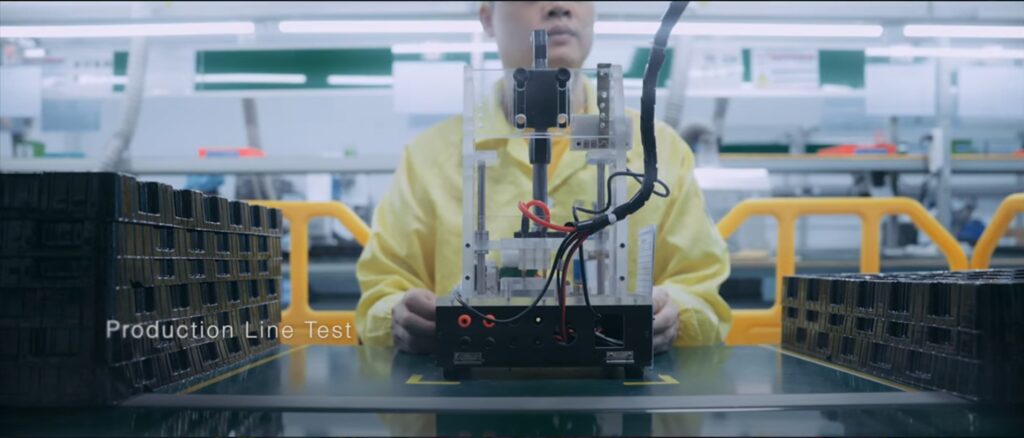

boqi’s R&D and manufacturing facilities are equipped with advanced testing instruments, precision molding machines, and automated production lines. From electronic design to structural optimization, every process is executed under strict standards. This integration of technology and craftsmanship allows us to create LED drivers and dimmers that not only perform with reliability and efficiency but also feature refined design and exceptional build quality.

- Precision Engineering Equipment

- Comprehensive Testing Systems

- Integrated Design & Production Workflow

Probing into Every Spec

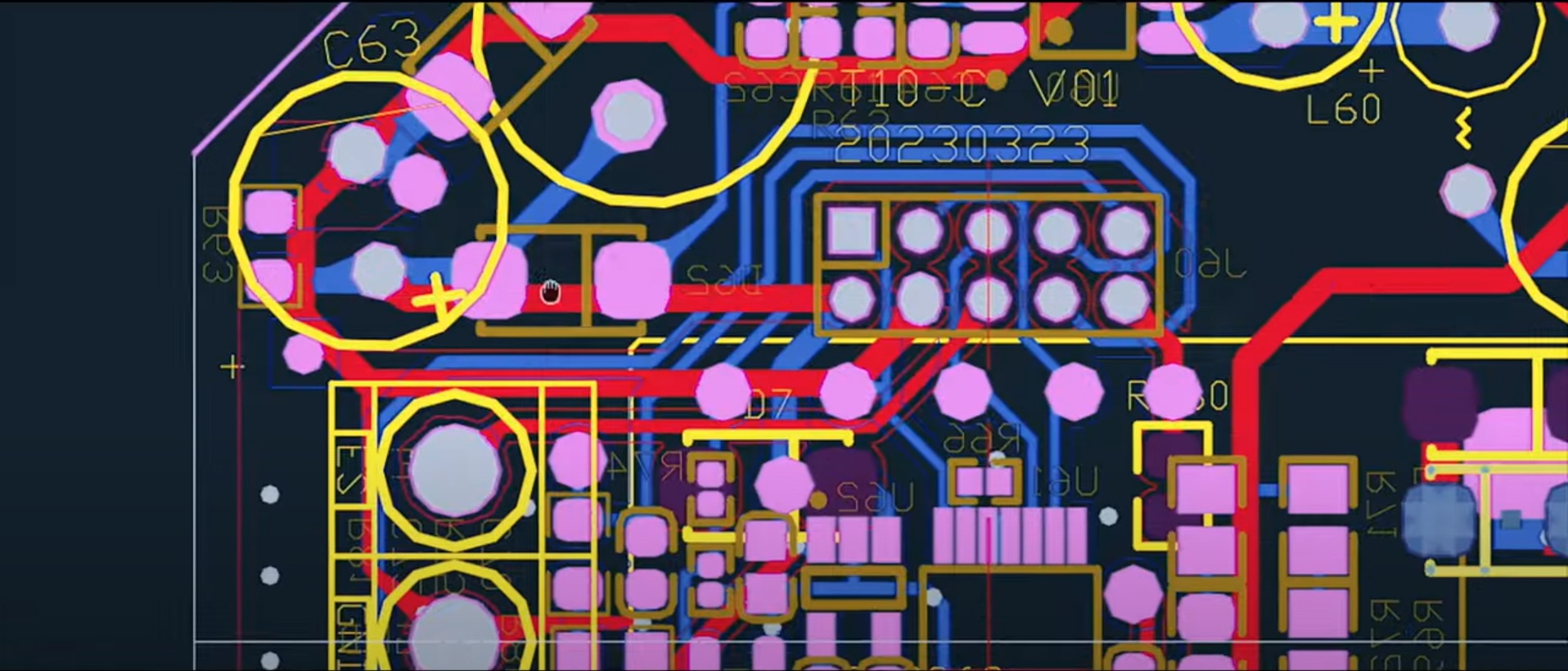

At Boqi, precision defines our development process. Every LED driver and dimmer is engineered through deep technical analysis and data validation to ensure flawless performance and compatibility across applications.

Electrical Performance Evaluation

Each design is tested for voltage, current, and efficiency stability to guarantee reliable and safe operation.

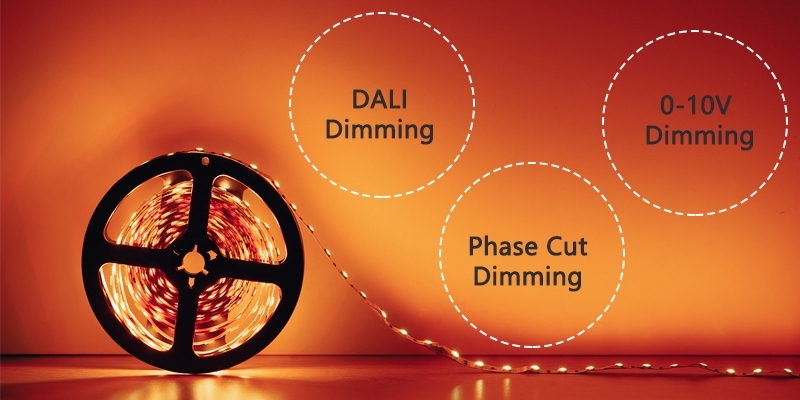

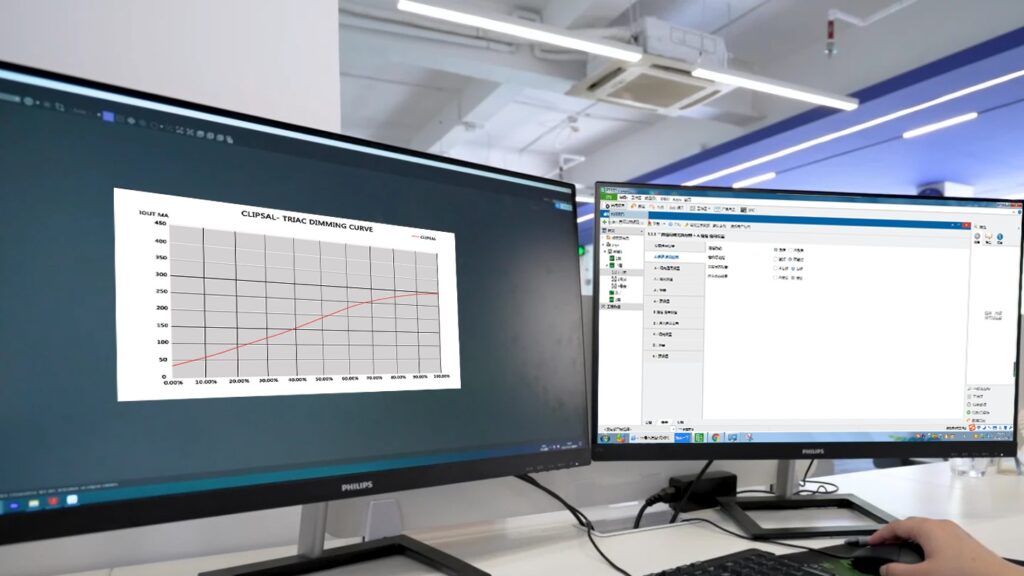

Dimming Compatibility Verification

Boqi conducts multi-protocol tests — including TRIAC, 0-10V, and DALI — to ensure smooth, flicker-free dimming performance.

Thermal Management Analysis

We simulate and measure heat dissipation to ensure optimal temperature control and extended product lifespan.

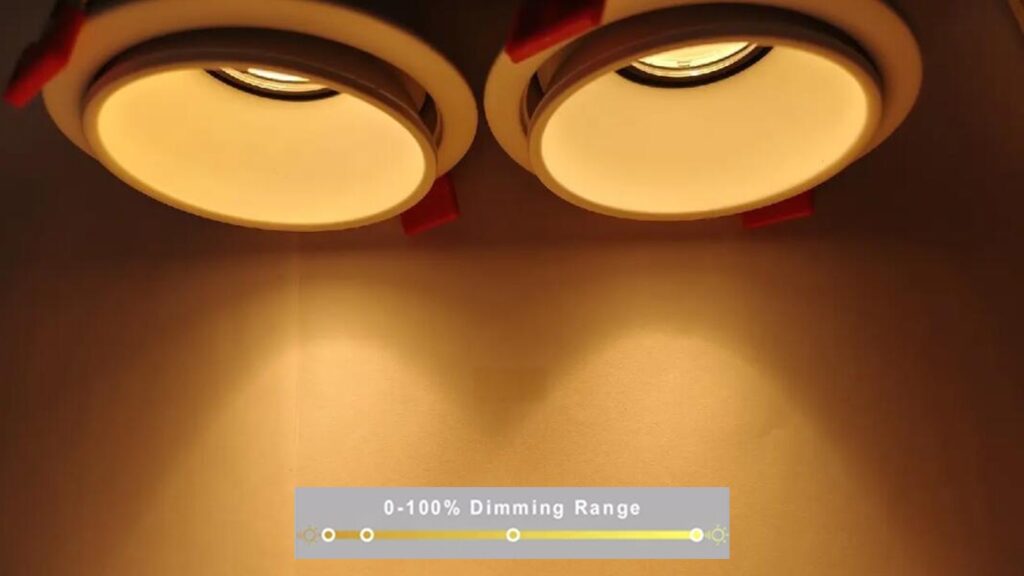

Flicker & Dimming Smoothness

Tested under IEEE 1789 to ensure visual comfort and healthy lighting output.

Material & Component Inspection

Only qualified components from trusted suppliers are approved after rigorous reliability testing and certification checks.

Functional & Lifetime Testing

Products are run through long-hour aging and durability tests to confirm consistent output and lasting performance.

Our 7-Day Approach Helping You Stay Ahead of the Game

Insight & Concept (Day 1–3)

We start by understanding your market goals, product requirements, and application environments. Through close collaboration, our engineers translate your ideas into feasible lighting solutions.

Market-Oriented Design Thinking

– Each project begins with an in-depth understanding of your brand and end-user needs.

Feasibility & Technical Evaluation

– We assess component selection, dimming compatibility, and compliance requirements before moving to design.

Engineering & Prototyping (Day 4–6)

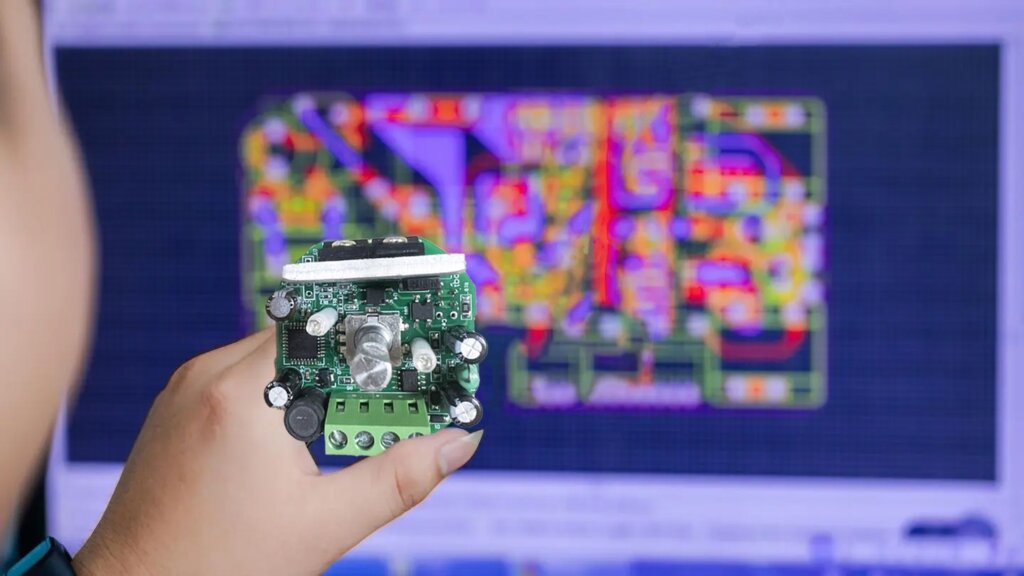

Our R&D team transforms concepts into working prototypes using advanced simulation and precision engineering tools.

Rapid PCB & Housing Development

– Circuit and mechanical design are executed simultaneously to speed up delivery.

Comprehensive Functional Testing

– Each prototype undergoes dimming, temperature, and protection tests to ensure performance stability.

Validation & Optimization (Day 7–9)

After prototype approval, we refine every detail to meet production standards and ensure seamless transition to mass manufacturing.

Specification Verification

– Detailed performance data and BOM documentation are finalized for production readiness.

Design Optimization for Production

– We adjust key parameters for reliability, manufacturability, and long-term durability.

Want To Be the Next Winning Brand?

boqi’s LED drivers, LED dimmers and services give you an absolute edge over your competitors.