Quality Control

Global Certifications, Trusted Quality

Boqi is proud to meet international standards with certifications including TUV, CE, CB, SAA, and RoHS — turning these benchmarks into our everyday manufacturing discipline.

We collaborate with world-renowned component suppliers such as NXP, TI, ON, and ST, ensuring every product is built on a foundation of proven reliability.

From raw material inspection to finished product testing, our fully standardized quality process delivers the consistency and performance that keep our clients ahead in the market.

boqi 4-Step

Quality

Management System

Verifying Qualification of Raw Material Suppliers

Self-Purchased Raw Materials & Inspection

Standardized In-Process Quality control

Finished Products Inspection

From Every Part of The LED Driver...

At Boqi, we believe that true reliability starts with attention to every detail. From raw materials to finished products, each part of the LED driver is carefully engineered, tested, and verified to ensure outstanding performance and long-term stability. Our commitment to quality is reflected in every component and every process.

High-Quality Components

We source ICs, capacitors, and semiconductors from world-class suppliers such as NXP, TI, ON, and ST. These premium parts form the backbone of stable, efficient, and safe LED driver performance.

Precision PCB Design

Our PCB layouts are optimized for thermal management, electromagnetic compatibility, and signal stability. Each board undergoes strict inspection to ensure no defects before entering the assembly line.

Advanced Power Circuitry

boqi engineers design power circuits to maximize efficiency, minimize energy loss, and provide reliable dimming performance across TRIAC, 0-10V, DALI, and other protocols. Every circuit is validated through real-world stress tests.

Samples – The First Step to Reliable Production

At Boqi, every project begins with a sample that bridges high-quality components e reliable mass production.

We push each sample to its limits, testing it repeatedly under the harshest conditions to guarantee long-term performance and stability.

Once approved, our QC team captures every detail — recording full specifications and delivering a precise BOM sheet — so your design moves into mass production quickly, smoothly, and worry-free.

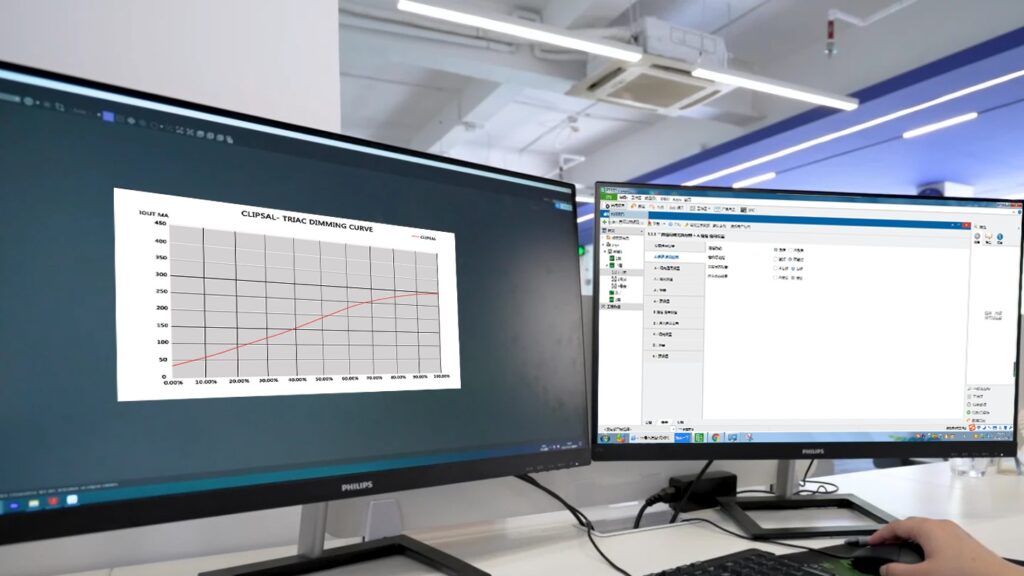

Dimming Tests:

For Premiun Dimming Performance

boqi conducts comprehensive dimming tests to guarantee smooth, reliable performance. They are

Dimming Range Test – Measure dimming performance from 100% down to minimum (e.g., 1%).

Dimming Compatibility Test – Test with TRIAC, 0-10V, DALI, DMX, or other protocols (depending on model).

Flicker Test (IEEE 1789) – Ensure low flicker levels to meet health and comfort standards.

Dimming Response Speed Test – Check for latency between control signal change and light output.

Electronic Performance Tests:

For Safe Applications

Output Current Accuracy Test

– Ensure output current matches the driver’s specification (critical for constant current drivers).

Power Factor (PF) Measurement

– Confirm PF ≥0.9 (or as specified) to meet energy standards.

Output Voltage Regulation

– Measure voltage stability under no-load, half-load, and full-load conditions.

Efficiency Test

– Measure driver efficiency at various load levels (e.g., 25%, 50%, 75%, 100%).

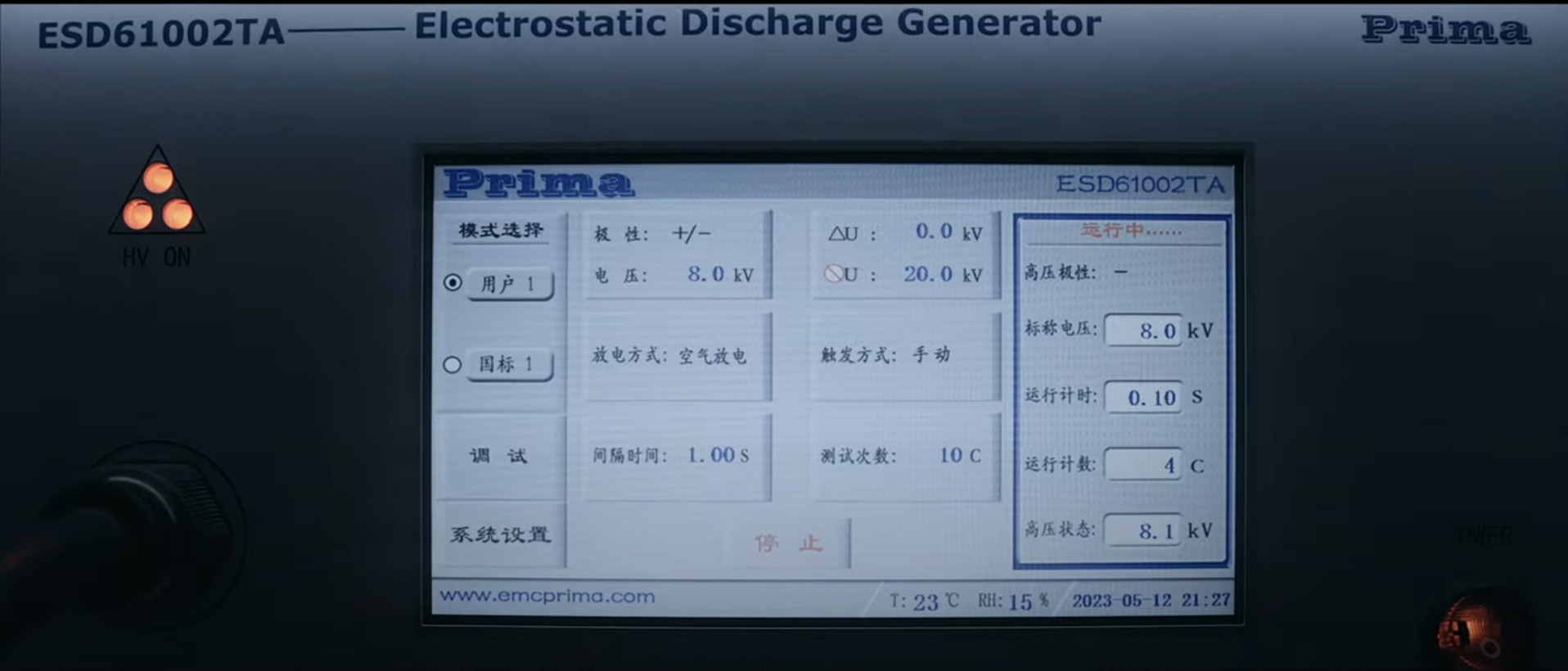

Extreme Challenge Tests:

For Every Harsh Condition

boqi LED drivers undergo extreme challenge tests to ensure reliability even in the toughest environments. We simulate real-world stress conditions to guarantee stable performance, long lifespan, and safety for demanding projects.

High/Low Temperature Endurance – Test drivers in extreme heat and cold to ensure consistent output.

Surge & Overload Protection Test – Validate safety under power surges, overloads, and abnormal voltage conditions.

Assembly Controlled & Checked Seriously

boqi takes LED driver assembly seriously, implementing strict process control at every stage. Each unit is assembled following standardized work instructions, with multiple checkpoints to verify soldering quality, component placement, and wiring accuracy.

Our QC team performs in-line inspections and final functional tests, ensuring every driver meets design specifications before leaving the factory. This rigorous approach guarantees consistent quality, reliability, and safety for your lighting projects.

Want To Be the Next Winning Brand?

boqi’s LED drivers, LED dimmers and services give you an absolute edge over your competitors.