Pulse Width Modulation (PWM) dimming is a popular technique used to control the brightness of LEDs. It is widely used due to its efficiency and ability to provide precise dimming control. This article explores PWM dimming, its advantages, technical details, and how it compares to other dimming methods.

PWM Dimming for LED drivers uses Pulse Width Modulation. It adjusts the brightness of LEDs by switching them on and off at a high frequency. By varying the duty cycle, the average power delivered to the LED changes, thus controlling the brightness. PWM dimming is preferred for its efficiency. It gives precise control over LED brightness. This makes it suitable for many lighting applications.

To understand PWM dimming better, we need to delve into the specifics of how it works and why it is preferred over other methods.

An Insight on Dimming

Constant Current Reduction (CCR)

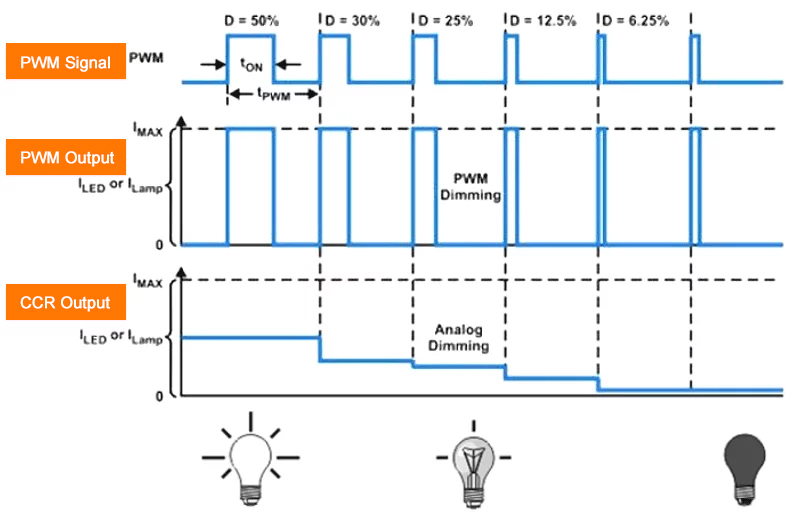

LEDs can be dimmed in various ways. The most common are Constant Current Reduction (CCR) and Pulse Width Modulation (PWM). CCR reduces the current supplied to the LED, thereby lowering its brightness. This method is simple. But, it may change the color and efficiency of the LED. Lowering the current can cause CCR to change the LED’s color or make it less bright. Also, this method might create more heat. This heat could reduce the life of the LED components.

The constant current reduction has its application in the following areas.

- Situations where the drivers are far away from the power source

- Damp areas and outdoor applications

- Areas of strict electromagnetic interference(EMI) standards

Pulse Width Modulation (PWM)

On the other hand, PWM dimming controls the brightness by rapidly switching the LED on and off. The average power delivered to the LED is adjusted by changing the duty cycle of the PWM signal. This method maintains color consistency and is more efficient, making it a preferred choice in many applications. PWM modulates the pulse width. It ensures the LED gets consistent power in short bursts. This lets the LED maintain its color. Also, PWM can be easily controlled by digital systems. This makes it highly compatible with modern electronic controls and smart lighting systems.

PWM has its application in the following areas.

- LED driver dimming

- Solar panels

- Motors

What is PWM Dimming?

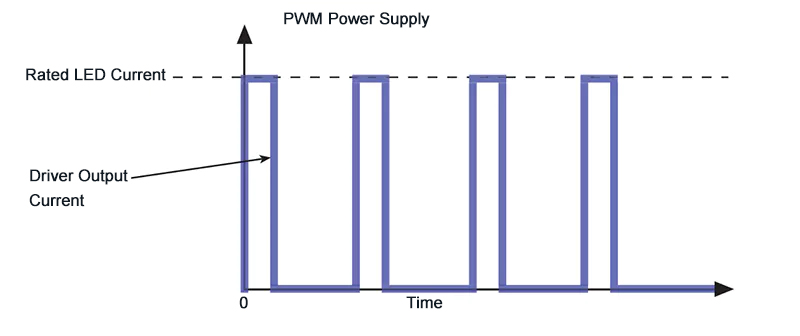

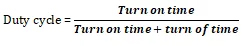

PWM dimming involves using a square wave signal to control the power delivered to an LED. The signal switches between on and off states at a high frequency. The duty cycle is the proportion of time the signal is on. It determines the average power and thus the brightness of the LED. For example, if the duty cycle is set to 50%, the LED will be on for half the time and off for the other half, resulting in 50% brightness. It switches on and off quickly. The human eye sees it as a dimming effect, not a flickering light.

For example, a 50% duty cycle means the LED is on half the time and off the other half, resulting in 50% brightness. By adjusting the duty cycle, precise control over brightness can be achieved. Additionally, PWM dimming is not limited to simple on-off patterns. The duty cycle can be varied smoothly. This allows for gradual changes in brightness. This is useful for applications that need smooth dimming. These include architectural or stage lighting. Also, microcontrollers can implement PWM dimming. This makes it versatile for various LED driver designs.

Why PWM is Used for Dimming LEDs

PWM is used for dimming LEDs because it offers several advantages:

– Effektivitet: PWM dimming does not dissipate power as heat, making it more energy-efficient. Analog dimming methods can waste energy by making excess power into heat. PWM controls power more precisely. It ensures minimal energy loss. This speed is key in lights that use batteries or are portable. Saving power is crucial there.

– Precision: It provides accurate control over brightness levels. The ability to finely adjust the duty cycle allows for a wide range of brightness settings, from very dim to full brightness. This precision makes PWM dimming suitable for applications where precise lighting control is essential, such as in medical devices, photography lighting, and display backlighting.

– Consistency: Maintains the color temperature and quality of the LED light. Because the LED is always operating at its full rated current during the “on” periods, the color temperature remains stable. This is a significant advantage over analog dimming, which can cause color shifts at lower current levels. Consistent color quality is vital in applications like retail lighting and museum displays. Accurate color is crucial in these places.

– Kompatibilitet: Easily integrated with digital controls and microcontrollers. Many digital devices can make PWM signals. These devices include microcontrollers, PLCs, and even some simple timers. This compatibility allows for easy integration into smart lighting systems and automated control setups, enabling features like remote dimming control, programmable lighting schedules, and dynamic lighting effects.

These benefits make PWM ideal for applications. These range from household lighting to industrial and automotive uses. In cars, for instance, PWM dimming is used in dashboard and headlight dimming. It’s also used in interior ambient lighting. It provides reliable and efficient control in changing conditions.

Technical Details on How PWM Dimming Works in LED Drivers

PWM dimming in LED drivers involves generating a high-frequency square wave signal. This signal is fed into the LED driver, which then modulates the power supplied to the LED based on the duty cycle of the PWM signal. The LED driver acts as an intermediary, ensuring that the LED receives the correct amount of power to achieve the desired brightness. The modulation process involves switching the current to the LED on and off at high speeds. The length of the “on” time is set by the PWM signal’s duty cycle.

The LED driver typically includes a microcontroller or a dedicated PWM controller IC that generates the PWM signal. The frequency of the PWM signal is chosen to be high enough to avoid visible flicker, usually above 200 Hz. At this frequency, the on-off transitions are too fast for the human eye to detect, resulting in a smooth dimming effect. The microcontroller or PWM controller IC adjusts the duty cycle. It does so based on user input or programmed settings. This allows for dynamic and responsive LED brightness control.

To ensure reliable performance, the LED driver must be designed to handle the specific characteristics of the LED load. This includes the LED’s forward voltage. It also includes its current rating and thermal needs. The drivers may have feedback. It monitors the LED’s performance and adjusts the PWM signal. This keeps brightness and color consistent under varying conditions. Also, the LED driver may have protection features. These include overcurrent protection, thermal shutdown, and short-circuit protection. They protect both the LED and the driver circuit.

PWM as a Dimming Signal: Duty Cycle and Frequency

The duty cycle of a PWM signal is the ratio of the on time to the total period of the signal. For instance, a duty cycle of 25% means the signal is on for 25% of the time and off for 75%. Adjusting the duty cycle changes the average power delivered to the LED, thus controlling its brightness. The duty cycle’s flexibility allows for a wide range of brightness levels. They go from nearly off to fully on. It provides precise and smooth dimming control.

The frequency of the PWM signal is also crucial. Higher frequency makes dimming smoother and avoids flicker. This is especially true in applications with motion, like video recording. Frequencies above 25 kHz are recommended for flicker-free dimming. At these high frequencies, the PWM signal switches on and off so rapidly. This flicker is so fast that humans and high-speed cameras can’t see it. This is key in pro lighting setups. Flicker can harm video quality and viewer comfort.

In practice, the PWM frequency choice depends on the LED’s needs and its use case. For example, in architectural lighting, a frequency of around 1 kHz may be enough to avoid visible flicker. But, in high-performance video lighting, a frequency of 25 kHz or higher may be needed for flawless performance. The duty cycle and frequency must be calibrated carefully. They balance brightness, efficiency, and flicker-free operation. Factors include the LED’s response time and the system’s thermal traits.

PWM som utgång för LED-drivdon

In a PWM-based LED driver, the output is a modulated current that corresponds to the PWM signal. The LED driver converts the PWM signal into a corresponding current, which then drives the LED. This method ensures the LED gets the right amount of current. This keeps its brightness and efficiency. Modulating the current allows for precise control over the LED’s light output. This ensures consistent performance across a wide range of brightness levels.

The LED driver achieves this by rapidly switching the current to the LED on and off in sync with the PWM signal. During the “on” periods, the LED receives full current, producing its maximum light output. During the “off” periods, the LED receives no current, resulting in no light output. The driver adjusts the ratio of “on” to “off” periods (the duty cycle). This control sets the average current and, thus, the average light output of the LED.

This approach has several advantages. First, it allows the LED to operate at its full efficiency during the “on” periods, minimizing energy loss and heat generation. Second, it maintains the LED’s color consistency, as the LED always operates at its rated current during the “on” periods. Third, it provides precise control over the LED’s brightness. This allows smooth dimming and dynamic lighting effects. Also, PWM-based drivers can easily connect to digital control systems. This allows for programmable and remote control of the lighting setup.

Comparing PWM Dimming with Other Dimming Methods

PWM dimming has several advantages over other methods:

– Analog Dimming: Involves adjusting the current supplied to the LED. While simple, it can lead to color shifts and is less efficient. Analog dimming reduces the current gradually. This can cause the LED to emit light at varying intensities and maybe change its color. This method also tends to dissipate more power as heat, reducing the overall efficiency of the system.

– Phase-Cut Dimming: Used in AC-powered LED drivers, it chops the AC waveform to reduce power. It can introduce flicker and compatibility issues with some LED drivers. Phase-cut dimming works by cutting off a portion of the AC waveform, effectively reducing the average power delivered to the LED. This method can cause compatibility issues with some LED drivers. This leads to flicker and poor performance. It also requires more complex circuitry to implement, which can increase the cost and complexity of the lighting system.

PWM dimming is more efficient. It also provides precise control and keeps color consistent. It is better in many applications. PWM dimming modulates power with a high-frequency signal. It avoids the issues of analog and phase-cut dimming. PWM dimming is a more reliable and flexible solution. Also, PWM dimming works with digital control systems. It enables advanced features such as programmable dimming profiles, remote control, and integration with smart home systems.

Realizing PWM Dimming Drivers in the Market

PWM dimming drivers are increasingly important in LED lighting. However, it is crucial to understand that there are two distinct methods for implementing PWM dimming drivers. Let’s explore these methods.

Fake PWM Dimming

The fake PWM dimming method involves converting PWM inputs into an analog control signal. This method uses a resistor-capacitor (RC) filter within the driver. The RC filter smooths the PWM signal into a DC voltage proportional to the duty cycle. One advantage of fake PWM dimming is that it is noise-free since the LED current remains continuous at the output.

However, this method has significant drawbacks. The peak value of the PWM signal must be 10V to ensure accuracy, which can be a limitation. Also, the RC parameters limit the PWM signal’s frequency. This reduces the dimming system’s flexibility and performance.

Real PWM Dimming

In real PWM dimming, the LED currents switch on and off at the specified frequency and duty cycle. A microcontroller (MCU) inside the driver detects the peak voltages of the PWM signal, allowing for precise control. Real PWM dimming supports a broader range of PWM frequencies and preserves the white point of the LED output. It also accommodates a higher reference voltage, reducing offset errors.

All boqi drivers, for example, integrate an MCU to facilitate true PWM dimming. This enables their drivers to accept a wide range of PWM signal voltages, from 3.8V to 10V, making them compatible with various PWM signals such as the commonly used 5V PWM signal.

Users need to select the PWM dimming mode in the driver programming software to utilize this functionality.

Slutsats

In conclusion, PWM dimming is an effective and efficient method for controlling LED brightness. Its precision and adaptability make it a preferred choice in various applications. Understanding its mechanics and benefits can help in selecting the right dimming solution for your needs. Choose reputable providers like boqi. They ensure you get high-quality dimbara LED-drivdon. The drivers offer exceptional performance and reliability.