LED Driver is a main part of the led lighting, its quality can cause a lighting’s life. So let us talk about LED Driver.

LED Drivers are usually 2 modes, like constant current and constant voltage. If we sort them by the input, they are high voltage input, like 110V or 220V, or low voltage. 12V, 24V and 48V etc.

Constant current mode is common in our life, the panel lights, ceiling lights, track lights, and street lights are usually with the CC LED Drivers.

How to confirm a LED Driver is good, is vital.

1. What is the parts of a LED Driver

Here is a diagram of a LED Driver.

2. What is the roles that the parts act

Electromagnetic filter

It is mainly to filter out external interference and reduce the EMI from the LED Driver unit.

Rectifier filter

Make the power from AC to DC.

Varistor

The protector in the LED Driver circuit, like a fuse.

Transformer and Mosfet

The transformer converts high voltage which is delivered by the Triode, into low voltage.

Protection Circuit

The auto protection happens when LED Driver is in a short circuit, over-voltage or over current, etc.

PFC Circuit

A friendly circuit to the external power grid is also mandatory in some electrical standards, like China, it can reduce the interference from the LED Driver to the power grid.

It seems like it is abstract, and not easy to understand. Let us see a real led driver insides (open frame version).

3. What is the guarantee of the LED Drivers

IC

Which is the brain of a LED Driver, its quality cause the whole led driver.

Transformer

The power and temperature resistance of the LED Driver depends on it.

Electrolytic capacitor and MLCC

They can decide how long a LED Driver works

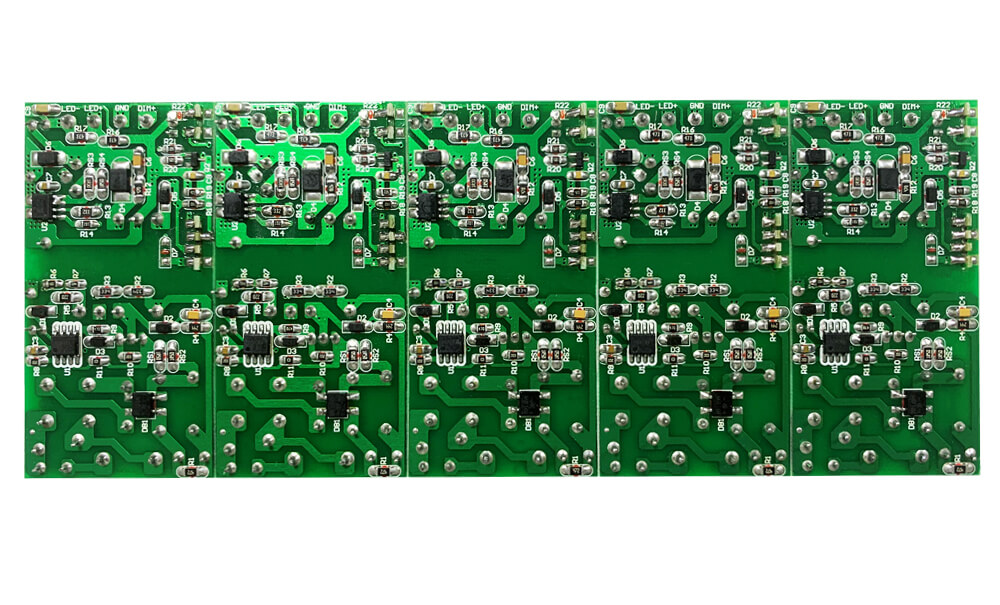

The circuit design and welding technology of LED Driver

Far Away From a professional perspective,it can be distinguished by some intuitive methods, such as whether the component layout is neat and orderly, and whether the solder joints are clean and intact. The process quality of wave soldering is much better than that of manual soldering.

That is very vital that a factory should have a perfect QA and QC system for the parts and the complete testing of the LED Drivers, I would like to bring our boqi LED Driver as an example, see how we guarantee the quality of each led driver.

1. QA and QC testing line, tests if every part is qualified.

2. Automatic plug-in machine, accurately and efficiently insert materials into PCB

3. SMT Mounter

4. Automatic AOI visual inspection

5. Aging and high-temperature testing room

These devices can guarantee the manufacturing process is stable and accurate, decrease any flaw in our LED Drivers. Let our client can get a good quality LED Driver.

Click Here to read more about our LED Driver