I see many engineers stuck when they choose between 0–10V and 1–10V dimming. The wrong choice leads to flicker, wasted time, and unexpected cost.

0–10V uses a current-source control that reaches true dim-to-off, while 1–10V uses current-sink control that stops at 10%. This difference affects compatibility, installation, and final dimming quality.

Both standards look similar. Both use the same two wires. Both look simple. But they come from different times in lighting history. I learned this the hard way when I worked on mixed LED and fluorescent retrofit projects. That is why I want to break the topic down with simple language and real stories.

Understanding the Basics: What 0–10V and 1–10V Actually Mean?

Many buyers assume both standards behave the same. They look identical on drawings. They both use low-voltage analog signals. But their logic is very different.

0–10V dimming sends a voltage from 0 to 10V to control brightness, while 1–10V dimming pulls current to set brightness between 10% and 100%.

How the Two Systems Work at Their Core

0–10V: A Current-Source Philosophy

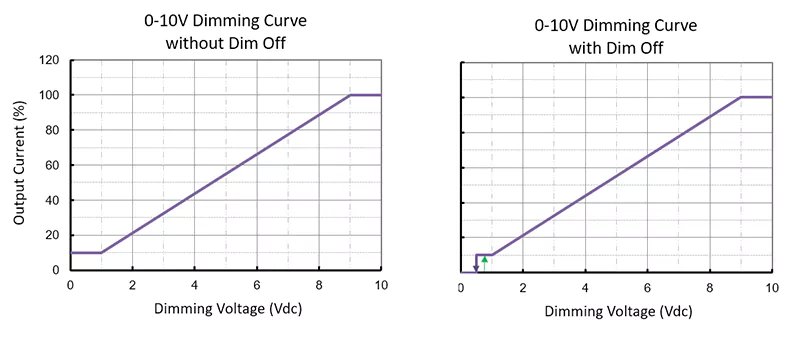

A 0–10V driver creates a small reference voltage. The dimmer reduces that signal down to 0V. When the signal reaches 0V, the LED driver outputs zero light. This is why 0–10V became the standard for LED systems that need full dim-to-off.

1–10V: A Current-Sink Legacy

A 1–10V dimmer pulls current from the driver. It cannot reach below 1V. That means the lowest level stays around 10%. This system comes from fluorescent ballast control, where lamps cannot run below a certain arc current.

Quick Comparison Table

| Feature | 0–10V | 1–10V |

|---|---|---|

| Control Type | Current Source | Current Sink |

| Minimum Level | 0% (off) | ~10% |

| Origin | LED Lighting | Fluorescent Ballasts |

| Best Use | Architectural / deep dimming | Retrofits / legacy systems |

Both are analog, simple, and cheap. But they behave in different ways that matter a lot once you start a project.

How Each Standard Performs in Real-World Lighting Projects?

In real project installations, small details become big problems. I have seen installers mix both systems by mistake. The result is poor dimming and angry clients.

0–10V performs better when you need smooth deep dimming, while 1–10V is stable for older systems that do not need full dim-to-off.

Real Project Behavior Explained

Smoothness at Low Levels

0–10V gives better control near 1% because the driver understands every small change in the signal. 1–10V reaches its floor too early.

Stability Over Long Cable Runs

1–10V can drift when wire runs are long because it depends on pulling current. Voltage drop changes behavior. 0–10V handles this better.

Mixed Fixtures

Problems start when a project contains both LED drivers and old ballasts. A single dimmer cannot control both correctly. I had to explain this many times to buyers who wanted to save time and keep the existing dimmer.

Real-World Performance Table

| Scenario | Best Standard | Reason |

|---|---|---|

| Hotels and restaurants | 0–10V | Deep dimming and ambience |

| Warehouses | 1–10V | Simple retrofits, no need for 0% |

| Renovation with old ballasts | 1–10V | Matches existing infrastructure |

| High-end architectural | 0–10V | Smooth and quiet dimming |

Dimming is not only about numbers. It is about the feeling of the light in a space.

Why Lighting Manufacturers Still Use Both Standards?

People often ask me why manufacturers do not just drop 1–10V and move everything to 0–10V. The answer is simple.

Both standards remain because the market still has fluorescent legacy systems and many buildings are not ready to rewire.

Why 1–10V Still Exists

Legacy Buildings

Old buildings still use fluorescent ballasts with 1–10V control. Changing to 0–10V requires rewiring or replacing ballasts. This adds labor cost.

Budget Sensitivity

Some clients only want basic dimming. They do not need 0%. They do not want to pay more.

Stability for Certain Loads

Industrial environments sometimes prefer 1–10V because it is predictable. They are not focused on ambience.

Why 0–10V Dominates LED Lighting

LED Loves Low-Level Control

LED drivers can go down to almost zero current. 0–10V matches this behavior perfectly.

Energy Codes

Many regions require lights to dim-to-off with occupancy sensors. 1–10V cannot meet this requirement.

Better Fit for Today’s Lighting Designs

Architectural and commercial projects want flexible scenes and visual comfort. 0–10V offers more control.

The market is not uniform. Every region, building type, and project budget pulls the standards in different directions.

Technical Differences That Matter for LED Drivers & Dimmers?

The technical gap between 0–10V and 1–10V is small on paper, but huge in practice.

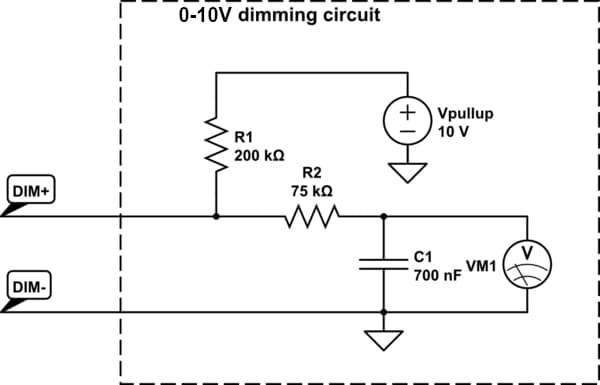

0–10V sends voltage from the driver, while 1–10V draws current from the driver. This changes how dimmers, drivers, and wire lengths behave.

Four Technical Points That Matter

1. Current Flow Direction

0–10V = the driver gives voltage

1–10V = the dimmer pulls current

This is the root of all compatibility problems.

2. Minimum Level Behavior

0–10V reaches true 0%

1–10V stops around 10%

This affects ambience and energy savings.

3. Control Curve

Most LED drivers use a non-linear curve. 0–10V dimmers usually match better. Mixing curves causes flicker at low levels.

4. Isolation and Safety

Good LED drivers provide isolation on the dimming circuit. Cheap ones do not. 1–10V drivers sometimes skip isolation because they only work in simple systems.

Technical Comparison Table

| Technical Factor | 0–10V | 1–10V |

|---|---|---|

| Current direction | From driver | Into driver |

| Dimming curve | Smooth low end | Limited low end |

| Deep dimming | Yes | No |

| Risk of mismatch | High if mixed | High if mixed |

Better hardware reduces risk, but it cannot change the core principles.

Compatibility Challenges and How boqi Solves Them?

I have helped many clients fix projects where dimming failed. The root issue was always compatibility. The dimmer expected one standard. The driver provided the other.

boqi solves compatibility challenges with clear labeling, dual-mode drivers, high-compatibility dimmers, stable dimming electronics, and detailed wiring guidance.

Common Compatibility Problems

Mixing 0–10V Drivers with 1–10V Dimmers

The result is unstable low-end performance. Lights may not turn off.

Long Cable Runs

Voltage drop changes the dimming curve. Both systems suffer but 1–10V breaks earlier.

Cheap Dimmers

Some dimmers output noisy signals. LED drivers amplify this noise into flicker.

How boqi Improves Compatibility

Clear Specifications

I always advise buyers to check:

– dimming type

– dimming current

– signal interpretation

– minimum voltage threshold

boqi labels these clearly.

Dual-Mode Drivers

boqi LED drivers can set 0–10V or 1–10V behavior based on buyers’ demand.

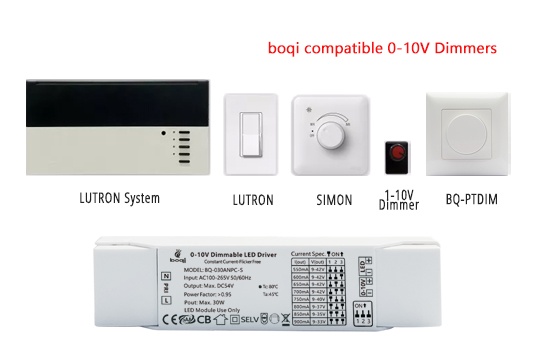

High-compatibility Dimmers

boqi has its own design 0-10V LED dimmer, which is highly compatible with boqi 0-10V dimmable LED Driver and other brands 0-10V LED drivers.

Clean Low-Noise Circuits

boqi designs reduce flicker and prevent jitter around 1V levels.

Wiring Guides

I include wiring diagrams for installers. This prevents mixing standards.

Good engineering reduces failures. Clear communication removes the rest.

Choosing the Right Standard for Your Next Project?

I often coach buyers on this decision. It always depends on project needs, budget, and existing infrastructure.

Choose 0–10V when you want deep dimming and modern LED behavior. Choose 1–10V when you are working with legacy ballasts or when dim-to-off is not required.

Simple Decision Framework

Choose 0–10V If:

- You want dim-to-off

- You use modern LED drivers

- You need smooth ambience

- You care about energy codes

- You plan new construction

Choose 1–10V If:

- You keep fluorescent ballasts

- You do not need 0%

- You want low system cost

- You retrofit without rewiring

Project Example Table

| Project Type | Recommended Standard | Reason |

|---|---|---|

| Luxury hotel | 0–10V | Deep dimming |

| Public school retrofit | 1–10V | Matches old ballasts |

| New warehouse | 0–10V | Sensors + off mode |

| Office renovation | Depends | Check existing wiring |

The right decision reduces cost and prevents client complaints.

Future Outlook: Will One Standard Replace the Other?

Many people expect 1–10V to disappear soon. But I do not think so. The industry moves slowly.

0–10V will continue to dominate LED lighting, but 1–10V will survive in retrofit markets because rewiring costs are high.

What I See Happening

LED Continues to Grow

This helps 0–10V because it matches LED behavior better.

Fluorescent Declines But Slowly

Millions of buildings still use fluorescent fixtures. They will not upgrade all at once.

Cost Pressure Remains

Some projects always pick the cheaper option.

Digital Protocols Grow

DALI, PWM, and wireless control will expand, but they will not kill analog dimming soon. Many buyers still want something simple.

My Long-Term Prediction

- 0–10V becomes the main analog system

- 1–10V becomes a legacy niche

- Digital protocols grow but coexist

Lighting evolves, but not in sudden jumps. The market carries both old and new demands.

Conclusion

Both dimming standards survive because they serve different needs. Choose the one that fits your project, not the one that looks “newer.”